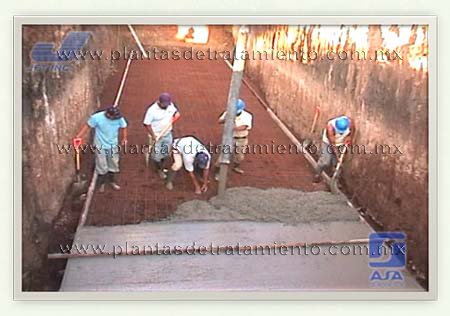

Installing Wastewater Treatment Plant starts by placing concrete modules with telescopic cranes, facilitating the set up process and making it more reliable and accurate. This arrangement is made strictly following the installation sequence obtained in pre-assembling.

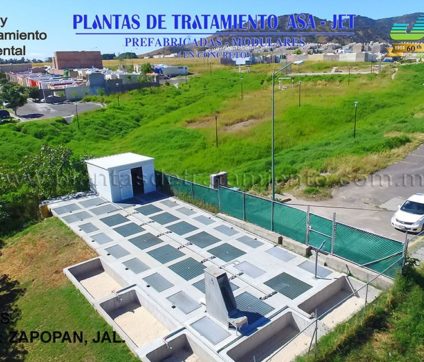

Following is the installation of electromechanical equipment: aeration unit, piping, nozzles, control panel and chlorinator Jet. The starting up is made with various stability tests. This tune-up process is done according to design parameters such as flow rate, level of contamination of wastewater, cycles and aeration capacity, in order to deliver an optimum operating wastewater treatment plant without generating odors that fulfills the relevant environmental standards.

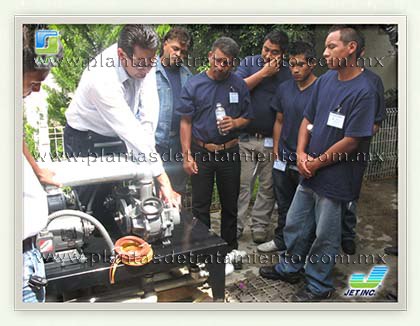

Finally, an ASA / JET plant operation certification course is offered, explaining in detail, both theoretically and practically, the different operating and preventive maintenance routines. At the end of the course, a corresponding Certification is given to all the attendees, along with the Operation and Maintenance Manual and an interactive video describing in a simple and detailed form the routines and controls.

Observance of these routines guarantees a stable and efficient operation of the plant.